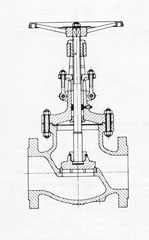

Class 150~1500 Cast Steel Globe Valve

Caratteristiche:

- OS&Y, Rising stem, Plug Disc

- Bolted Bonnet,Threated or welded seat ring

- Body and cover materials: ASTM A216 WCB,A217 WC6,A351 CF8,A351 CF8M, A351CF3, A351CN7M and according to customer request

According to following standards:

- Design and Manufacture: ANSI B16.34, BS 1873

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: ANSI B16.5,

- Butt welded end: ANSI B16.25

- Test and inspection: API598

|

|

|

Info tecniche

|

MATERIALS |

|

|

Part name |

Material |

|

Grub screw |

Carbon steel |

|

Hand wheel nut |

Carbon steel |

|

Hand wheel |

Carbon steel |

|

Eye bolt and nut |

A 193 B7/A194 4~A193 B8/A194 8 |

|

Pin |

Carbon steel/SS |

|

Stem nut |

A 439-D2/cu-alloy |

|

Gland flange |

Carbon steel |

|

Gland bush |

Stainless steel |

|

Back seat |

Stainless steel |

|

Pisc nut |

CS+SS/SS/SS+STL |

|

Stem |

Stainless steel |

|

Seat ring |

See body material |

|

Disc |

|

|

Part name |

WCB |

LCB |

WC6 |

WC9 |

|

Stud and nut |

A193GrB7/A194Gr 2H |

A320 Gr L7/A194Gr 4 |

A193Gr B16/A194Gr4/7 |

A193 Gr B16/A194Gr 4/7 |

|

Gland Packing |

Graphite |

Graphite |

Graphite |

Graphite |

|

Gasket |

Spiral wound/Soft lron |

Spiral wound/Soft lron |

Spiral wound/SS304 |

Spiral wound/SS304 |

|

Bonnet |

A216 Gr WCB |

A352 Gr LCB |

A271 Gr WC6 |

A271 Gr WC9 |

|

Body |

A216 Gr WCB |

A352 Gr LCB |

A271 Gr WC6 |

A271 Gr WC9 |

|

Part name |

C5 |

C12 |

CF8 |

CF8M |

|

Stud and nut |

A193 Gr B16/A194 Gr 4/7 |

A193 Gr B16/A194 Gr 4/7 |

A193 Gr B8/A194 Gr 8 |

A193 Gr 8/A194 Gr 8 |

|

Gland Packing |

Graphite |

Graphite |

Graphite |

Graphite |

|

Gasket |

Spiral wound/Soft lron |

Spiral wound/Soft lron |

Spiral wound/SS304 |

Spiral wound/SS316 |

|

Bonnet |

A217 Gr C5 |

A217 Gr C12 |

A351 Gr CF8 |

A351 Gr CF8M |

|

Body |

A217 Gr C5 |

A217 Gr C12 |

A351 Gr CF8 |

A351 Gr CF8M |

| CLASS 150~1500 CAST STEEL GLOBE VALVE |

|

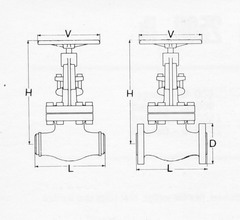

Dimensions |

|||||||||||||

|

ANSI 150 - Fig. 1090-1090W |

|||||||||||||

|

Size |

inch |

2 |

2-1/2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

|

L,L1-RF,BW |

mm |

203 |

216 |

241 |

292 |

356 |

406 |

495 |

622 |

698 |

787 |

914 |

978 |

|

L2-RTJ |

mm |

216 |

229 |

254 |

305 |

368 |

419 |

508 |

635 |

711 |

800 |

927 |

991 |

|

H |

mm |

330 |

390 |

410 |

475 |

540 |

585 |

725 |

825 |

940 |

1200 |

1270 |

1300 |

|

K |

mm |

200 |

250 |

250 |

300 |

350 |

350 |

450 |

500 |

600 |

600 |

650 |

650 |

|

Dimensions |

||||||||||||

|

ANSI 300 - Fig. 1092-1092W |

||||||||||||

|

Size |

inch |

2 |

2-1/2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

|

L,L1-RF,BW |

mm |

267 |

292 |

318 |

356 |

400 |

444 |

559 |

622 |

711 |

838 |

863 |

|

L-RTJ |

mm |

283 |

308 |

333 |

371 |

416 |

460 |

575 |

638 |

727 |

854 |

879 |

|

H |

mm |

350 |

425 |

485 |

520 |

565 |

655 |

825 |

920 |

1155 |

1250 |

1295 |

|

V |

mm |

200 |

250 |

300 |

300 |

350 |

350 |

500 |

600 |

700 |

700 |

450 |

|

Dimensions |

|||||||||

|

ANSI 600 - Fig. 1094-1094W |

|||||||||

|

Size |

inch |

2 |

2-1/2 |

3 |

4 |

5 |

6 |

8 |

10 |

|

L,L1-RF,BW |

mm |

292 |

330 |

356 |

432 |

508 |

559 |

660 |

787 |

|

L-RTJ |

mm |

295 |

333 |

359 |

435 |

511 |

562 |

664 |

791 |

|

H |

mm |

420 |

490 |

550 |

590 |

620 |

700 |

950 |

1140 |

|

V |

mm |

250 |

300 |

300 |

350 |

500 |

500 |

600 |

600 |

|

Dimensions |

||||||||

|

ANSI 900 - Fig. 1096-1096W |

||||||||

|

Size |

inch |

2 |

2-1/2 |

3 |

4 |

5 |

6 |

8 |

|

L,L1-RF,BW |

mm |

368 |

419 |

381 |

457 |

559 |

610 |

737 |

|

L-RTJ |

mm |

371 |

422 |

384 |

460 |

562 |

613 |

740 |

|

H |

mm |

495 |

540 |

600 |

655 |

670 |

780 |

1050 |

|

V |

mm |

300 |

350 |

350 |

500 |

500 |

350> |

350> |

|

Dimensions |

||||||

|

ANSI 1500 - Fig. 1098-1098W |

||||||

|

Size |

inch |

2 |

2-1/2 |

3 |

4 |

6 |

|

L,L1-RF,BW |

mm |

368 |

419 |

470 |

546 |

705 |

|

L-RTJ |

mm |

371 |

422 |

473 |

549 |

711 |

|

H |

mm |

550 |

580 |

625 |

750 |

925 |

|

V |

mm |

300 |

350 |

400 |

450 |

600 |